OILER MAKERS MARKS - ENGLAND

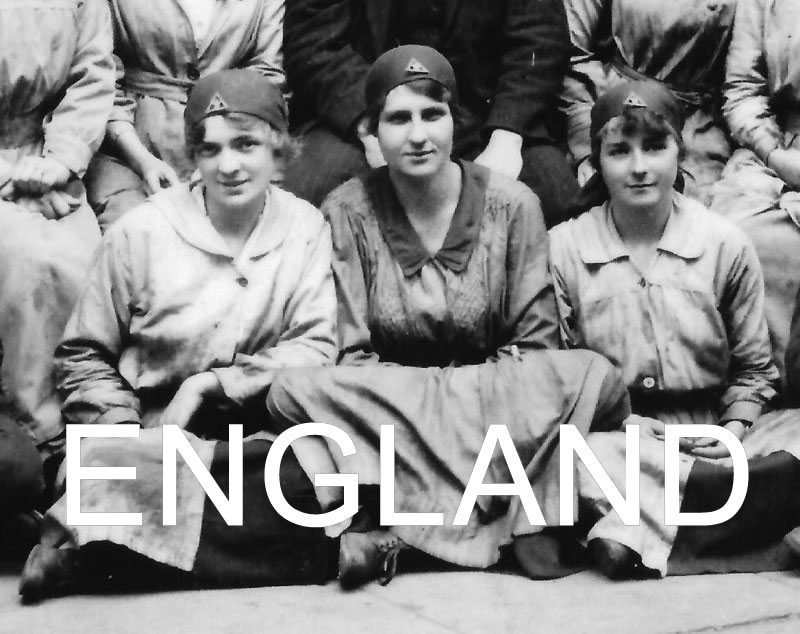

Photo notes: Photo detail from a larger group photo taken in 1916 of the staff of T. H. Nice, 21 Abbeygate Street, Bury St Edmunds, Suffolk, England. The firm of T. H. Nice, motor engineers and cycle makers, was one of many local firms recruited in 1915 by the East Anglican Munitions Committee to take on munitions production. Women munitions workers were known as “Munitionettes.” The three in the photo are wearing their newly issued triangular “On War Service” badges. Photographer unknown; Martyn Taylor (UK) collection; used with permission. [1]

|

The Ministry of Munitions 1915-1921 |

Thanks to the Ministry of Munitions (1915-1921) [7] and the Dilution Scheme, there is a trove of information available about the makers of Lee-Enfield oilers (oil bottles).

In the days before the Great War (1914-1919) the War Office was responsible for all aspects of weapons development and production. When the Royal Arsenals or Royal Small Arms Factories needed additional capacity, the War Department relied on ‘the trade’ – the contractors enumerated on the War Office List, to fill the gap. [8]

All that business-as-usual came crashing down during the ‘Shells Crisis’ of 1915 [9], when the press broke the story that the British Army’s big guns on the Western Front were rationed to firing only one or two rounds per day due to lack of ammunition.

The public was outraged, Parliament in uproar and the government in crisis.

The War Office’s failure could be traced to two issues – a failure to grasp the vast scale of the Great War, to imagine how many shells, supplies, guns, men and materials would be needed, and even more fundamental – if all the machinists, assemblers, mechanics, fitters, tool makers, inspectors and skilled workers were called up, who would be left to produce what was needed?

Over the strident objections of the War Office, the government established the Ministry of Munitions, which, to the outrage of the War Department, not only took over all Royal facilities, and to add further insult to the professional military, put civilians, “men of push and go”, [10] in charge of all contracting, supply chain and manufacturing.

The Ministry of Munitions took on the supply of labor with the Dilution Scheme, the plan that ordinary women – shop girls, ladies’ maids, cooks, waitresses, domestic servants – could be trained to do ‘men’s work’ and by diluting the work force, free up more men for service. Not only that, but civilian firms with no experience in war materials would be hired to produce munitions.

As much as traditionalists hated it, the plan worked. Thousands of small firms with no experience in any aspect of military equipment or supplies found that while War Department was conscripting almost every man on their payroll for active-duty service, at the same time the Ministry of Munitions was offering no-interest financing for the purchase of new equipment, would help train women to run that equipment, set prices and wages, and offer government contracts to buy their production. [11] More than a million women learned that they were perfectly capable of doing ‘men’s work’, that they could operate machinery, build shells, machine guns, mortars and the tools of war – and earn more money than they ever did in domestic service. The world would never be the same.

Thanks to the Ministry of Munitions, your Great War (1914-1919) manufactured rifle, bayonet or oiler was, either wholly or in part, undoubtedly made by a woman, a ‘munitionette’.

The list of oiler manufacturers below includes the Ministry of Munitions description of the firm’s pre-war work, what they did during the Great War, as well as the number of men and women they employed. Keep in mind that for most of these firms, prior to 1914, the number of women employed in non-clerical jobs was probably close to zero.

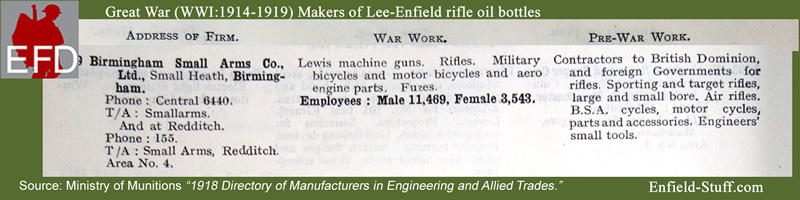

BIRMINGHAM SMALL ARMS COMPANY (BSA)

|

BIRMINGHAM SMALL ARMS COMANY - INSPECTION MARK Principal British small arms contractor 1861-1960's. Total rifle production in the millions. Prime government contractor; most oilers have a BSA inspection cartouche.

A poorly stamped and/or worn italic B may look like "13". |

|

BIRMINGHAM SMALL ARMS COMPANY - COMMERCIAL PRODUCTION Arms produced for commercial sales, including Colonies, police and foreign governments, are marked with the three-stacked Martini-Henry rifle logo, as are the oilers. |

|

BIRMINGHAM SMALL ARMS COMPANY - COMMERCIAL SALES INSPECTION MARK The BSA commercial inspection/view mark is a "V". |

ROYAL SMALL ARMS FACTORY (RSAF) SPARKBROOK

|

ROYAL SMALL ARMS FACTORY SPARKBROOK - INSPECTION MARK

Simple, straight-up, non-italic, "B". Factory sold to Birmingham Small Arms Co. (BSA) in 1906.

The Sparkbrook "B" is sometimes found on Mk IV oilers manufactured by Great War (1914-1919) contractors. Simplest explanation is probably no one thought it worth the bother to switch out a non-italic Sparkbrook inspection B cartouche for an italic Birmingham Small Arms inspection B cartouche. They're both "B" and both factories are BSA. |

|

ROYAL SMALL ARMS FACTORY SPARKBROOK Government factory 1883 - 1906. Factory sold to Birmingham Small Arms Company (BSA) in 1906. Mark found on Mk II, Mk III and Mk IV oilers. Total oiler production unknown. |

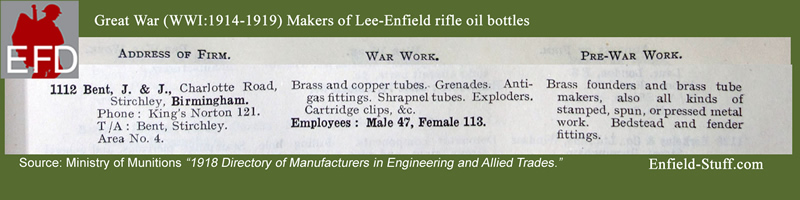

J & J BENT COMPANY

|

J &J BENT COMPANY Charlotte Rd, Stirchley, Birmingham, brassfounders. [4] [5]

Great War (1914-1919) contractor. [2] 250,000 total produced. [3]

Two types of marks noted. JJB-in-a-box most common. |

|

J & J BENT COMPANY Charlotte Rd, Stirchley, Birmingham [4] [5]

Great War (1914-1919) contractor. [2]

JJB-not-in-a-box is Type Two. Scarce. |

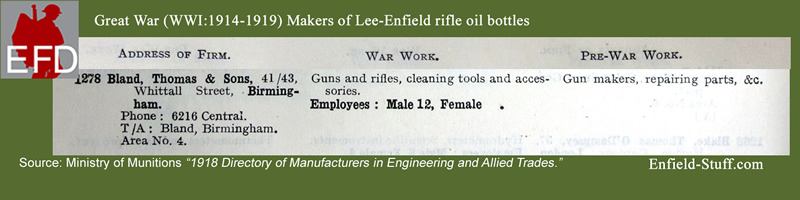

THOMAS BLAND & SONS LTD

|

THOMAS BLAND & SONS GUNMAKERS LTD 41/43 Whittal Street, Birmingham; later 4-5 William IV Street, Strand, London. [4] [5]

Great War (1914-1919) contractor. [2] 26,000 produced. [3]

The marks we have seen are lightly struck and easy to miss. |

|

THOMAS BLAND & SONS GUNMAKERS LTD

The 1954, 1960 and 1965 catalogs have exactly the same drawing on the cover. [6] |

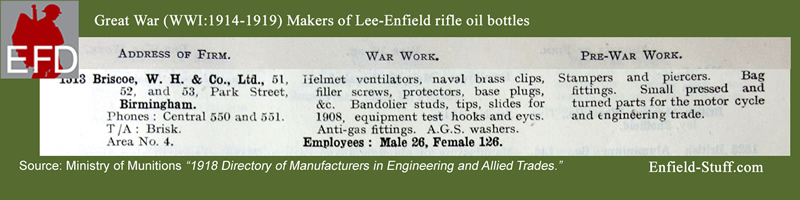

W.H. BRISCOE & COMPANY, LTD.

|

W. H . BRISCOE &COMPANY, LTD. 51-52 Park Street, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2] 150,000 produced. [3]

|

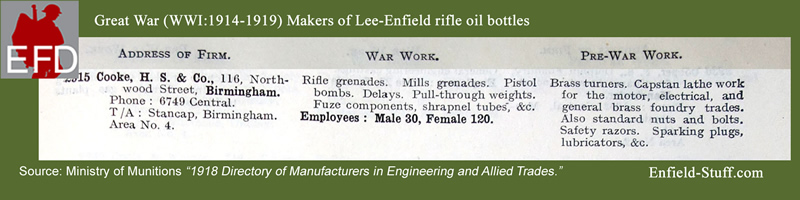

H.S. COOKE & COMPANY, LTD

|

H.S. COOKE & COMPANY, LTD. 116 Northwood Street, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2] Unknown production. [3]

Not uncommon |

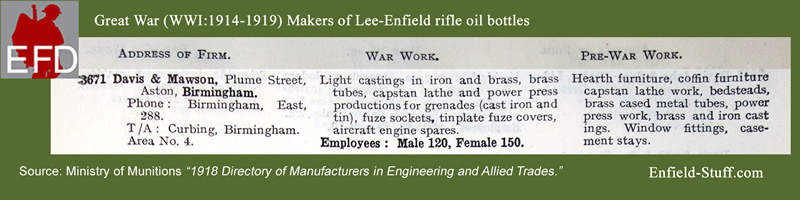

DAVIS & MAWSON

|

DAVIS & MAWSON Plume Street, Aston, Birmingham. [4] [5]

Not named by Skennerton as a Great War (1914-1919) contractor, but obviously did so. [2] Unknown number produced. [3]

Two variations of mark noted; the simpler D&M is Type One. |

|

DAVIS & MAWSON Plume Street, Aston, Birmingham, brassfounders, oilers. [4] [5]

Not named by Skennerton as a Great War (1914-1919) contractor. [2] Unknown number produced. [3]

The mark with a "B" beneath is rarely seen. Type Two. |

ROYAL SMALL ARMS FACTORY (RSAF) ENFIELD

|

ROYAL SMALL ARMS FACTORY (RSAF) ENFIELD - INSPECTION MARK Enfield Lock (No 13) is a lock on the River Lee Navigation, in the London Borough of Enfield. It gives its name to the surrounding area of Enfield Lock.

Principal government small arms manufacturing plant known as RSAF Enfield, or simply "Enfield". After England and NATO adopted the Belgian made FN-FAL rifle and 7.62mm round as standard in 1954, the end was inevitable. Plant closed in 1988.

A simple straight-up Times New Roman style "E" beneath a crown is the most common insepction/view mark. |

|

ROYAL SMALL ARMS FACTORY (RSAF) ENFIELD - MANUFACTURING MARK

Mark commonly found on RSAF Enfield manufactured rifles, bayonets and oilers.

Total oiler production unknown. Most commonly found on Mk I, Mk II and Mk III oilers. Later oiler production generally contracted out to suppliers. |

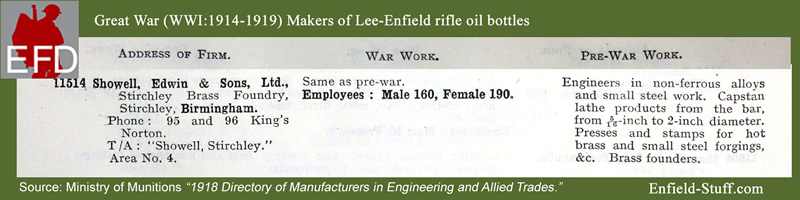

EDWIN SHOWELL & SONS, LTD.

|

EDWIN SHOWELL & SONS, LTD. Lower Loveday St. until 1902, then to bigger premises at Stirchley Brass Foundry, Charlotte Road, Birmingham. Founded as Showell and Barnes circa 1790; Showell name only from 1820. They were taken over by Josiah Parkes & Sons in 1956. [4] [5]

Great War (1914-1919) contractor. [2] 300,000 produced. [3]

Two variations of the same mark noted. Type One has more space between the letters. |

|

EDWIN SHOWELL & SONS, LTD. Stirchley Brass Foundry, Charlotte Road, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2]

Type Two variation has smaller letters, more closely packed. No one but a collector would notice the difference. |

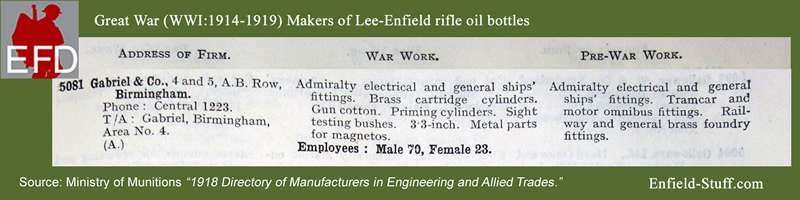

GABRIEL & COMPANY

|

GABRIEL & COMPANY (Percy) Gabriel & Company, founded as a brass foundry in 1884 at 4 & 5 AB Row, Birmingham, making brass components and fittings. [4] [5]

Great War (1914-1919) contractor. [2] 205,000 produced. [3]

More common Type One mark is curved and includes Birmingham. |

|

GABRIEL & COMPANY Brass foundry at 4 & 5 AB Row, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2] 1914 Specialities: Brassfoundry including Builders' and Cabinet Makers' requirements, Lavatory Fittings, Water Fittings, Electric Light, Railway Carriage, Tramcar and Motor Car Fittings and Ships' Brassfoundry [4] [5]

The Type Two mark is rarely seen. |

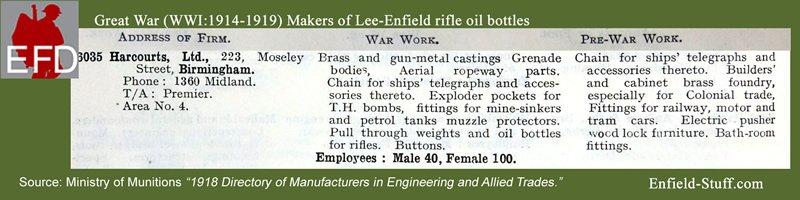

HARCOURTS, LTD.

M. HALLADAY & COMPANY

|

M. HALLADAY & COMPANY Name not found in official records. [4] [5]

Listed by Skennerton as a Great War (1914-1919) contractor. [2] Name not found in the 8,760 metalworking and similar firms listed in Ministry of Munitions lists 1916-1921. Closest name match is Halladay's, Ltd. which did engine work.

No reports of any marks that might be associated with this maker. |

HENRY RIFLE BARREL COMPANY

|

HENRY RIFLE BARREL COMPANY Hoxton, London

Known as HRB Company Ltd. 1878 - 1900. Acquired by Blenhelm Engineeering 1900; out of business circa 1902.

H inspection mark appears on some early service arms; this mark has been observed on Mk II and Mk III oilers. Rare. |

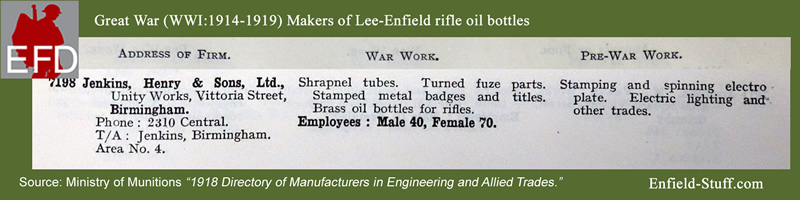

HENRY JENKINS & SONS, LTD.

|

HENRY JENKINS & SONS, LTD. Unity Works, Victoria Street, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2] 1,100,000 produced. [3]

With more than one million produced, one of the more common marks. |

SAMUEL HALL & SONS, LTD.

|

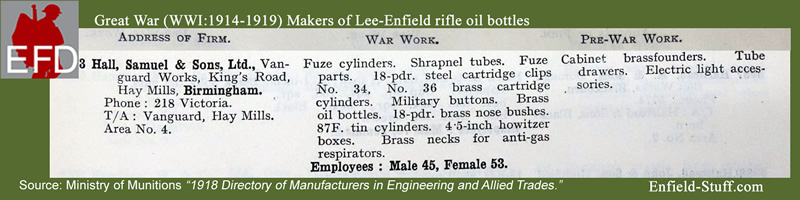

S. HALL & SONS, LTD. -OR- S. HEATH & SONS, LTD. ?

We have two firms with very similar names/initials. Both firms manufactured Lee-Enfield oilers during the Great War (1914-1919). Hall produced about 100,000 units; Heath about 400,000 units.

We have assigned the less common/numerous SH&S mark (without the Ltd.) to Hall & Sons and the variations with some form of "Ltd" in the mark to Heath & Sons.

After that, it gets more complicated. |

|

SAMUEL HALL & SONS, LTD. Vanguard Works, Hay Mills, Birmingham [4] [5]

Great War (1914-1919) contractor. [2] 100,000 produced. [3] |

SAMUEL HEATH & SONS, LTD.

|

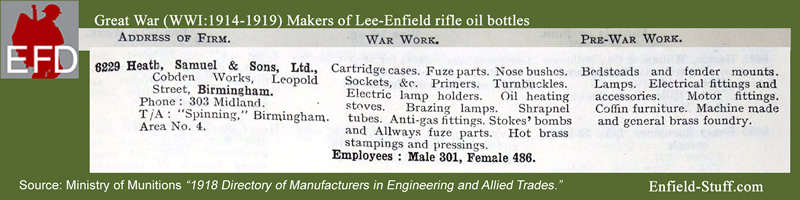

S. HALL & SONS, LTD. -OR- S. HEATH & SONS, LTD. ?

We have two firms with very similar names/initials. Both firms manufactured Lee-Enfield oilers during the Great War (1914-1919). Hall produced about 100,000 units; Heath about 400,000 units.

We have assigned the less common/numerous SH&S mark (without the Ltd.) to Hall & Sons and the variations with some form of "Ltd" in the mark to Heath & Sons.

After that, it gets more complicated. |

|

SAMUEL HEATH &SONS, LTD. Cobden Works, Leopold Street, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2] 400,000 produced. [3]

Three different markings noted; the simple one-line S.H&S Ld is Type One. |

|

SAMUEL HEATH &SONS, LTD. Cobden Works, Leopold Street, Birmingham. [4] [5]

Type Two mark is within a large triangle.

No idea of how many of each type mark were produced. |

|

SAMUEL HEATH &SONS, LTD. Cobden Works, Leopold Street, Birmingham. [4] [5]

Type Three mark is within a small triangle.

No idea of how many of each type mark were produced. |

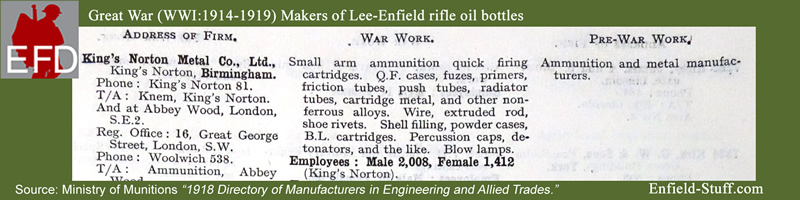

KINGS NORTON METAL COMPANY, LTD.

|

KINGS NORTON METAL COMPANY Kings Norton, Birmingham [4] [5]

Great War (1914-1919) contractor. [2] 100,000 produced. [3]

Ammunition company formed in 1890 at Kings Norton, South East of Birmingham. Ammunition headstamp KN on military contract ammunition. Plant absorbed by Explosives Trade Ltd. in 1918; ceased manufacturing in 1920; remaining assets liquidated 1930's. |

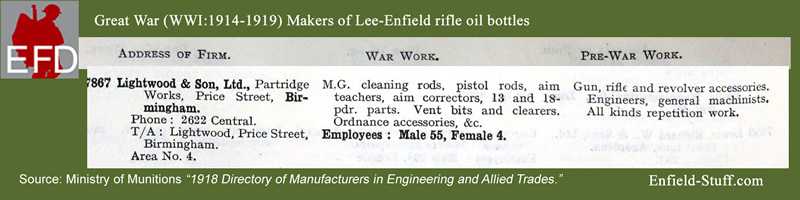

LIGHTWOOD & SON, LTD.

|

LIGHTWOOD & SON, LTD. Partridge Works, Price Street, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2] 84,000 produced. [3]

|

|

LIGHTWOOD & SON, LTD. Partridge Works, Price Street, Birmingham. [4] [5]

Their 1920 catalogue proclaims "Established 1859". It also shows they manufactured various sizes and shapes of oil bottles, among many other items. [6] |

LONDON SMALL ARMS COMPANY, LTD.

|

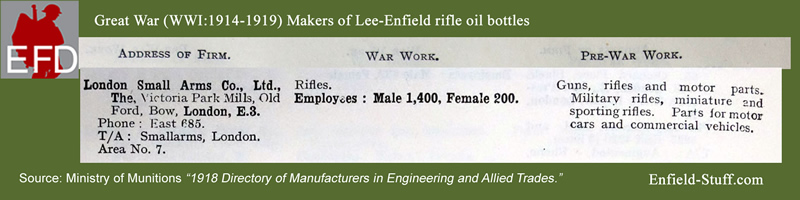

LONDON SMALL ARMS COMPANY, LTD. Victoria Park Mills, Old Ford, Bow, London.

Founded in 1866, factory at Victoria Park Mills; moved to Albion Works, Ossary Road 1921; out of business 1925. Rifle production 1888-1926 estimated to be 731,300.

Inspection/view mark found on Mk II and Mk III oilers; no other manufacturers marks. LSA inspection mark not seen on any oilers manufactured by others. X-inspection mark easily overlooked. Scarce. |

MARRIS'S LTD.

|

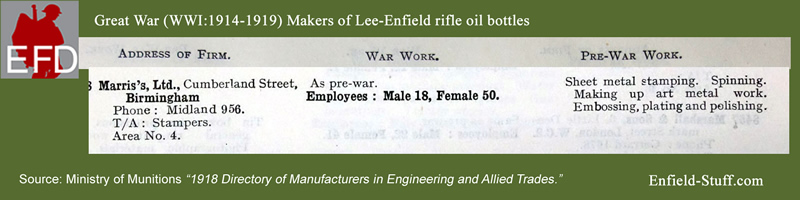

MARRIS'S LTD. Cumberland Street, Birmingham. [4] [5]

Listed by Skennerton as a Great War (1914-1919) contractor. [2] No reports of any marks that might be associated with this maker.

Marris's (no "Ltd.", but listed at the same address): "1922 Listed Exhibitor - British Industries Fair. Manufacturers of Fern Pots, Vases, Crumb Trays, Curbs, Coal Boxes, etc. Sole makers of "Sirram" Fitted Tea and Luncheon Baskets and Cases, and Boiling Sets." [4] |

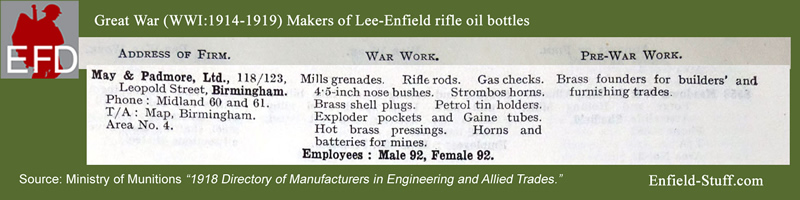

MAY & PADMORE, LTD.

|

MAY & PADMORE, LTD. 118/123 Leopold Street, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2] 100,000 produced. [3]

|

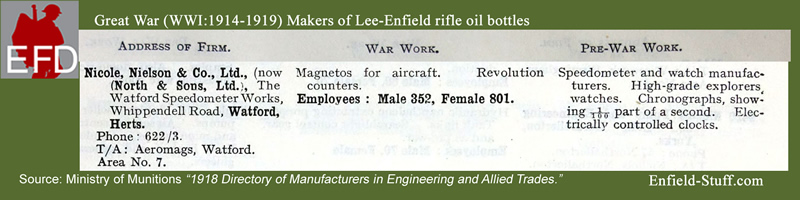

NICOLE, NIELSON & COMPANY, LTD.

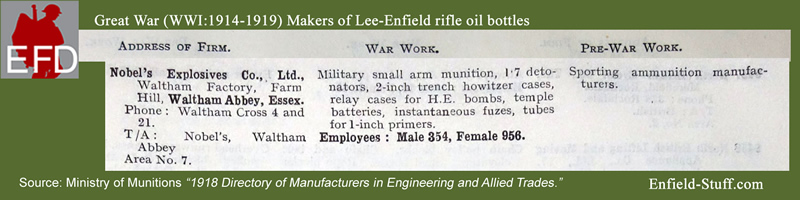

NOBEL EXPLOSIVES COMPANY, LTD.

|

NOBEL EXPLOSIVES COMPANY, LTD. Waltham Abbey, Essex. [4] [5]

Great War (1914-1919) contractor. [2] 53,000 produced. [3]

The Nobel Explosives headstamp found on military contract ammunition is a simple "N" (Not to be confused with the Times-New-Roman style "N" of the Royal Navy. The Royal Navy font has little embelishments, called serifs, at the head (top) and foot (bottom) of each leg of the letter.) The font used by Nobel was a sans-serif (French for "without serifs") font. Mark is tiny. Very scarce. |

|

NOBEL EXPLOSIVES COMPANY, LTD. Waltham Abbey, Essex. [4] [5]

The 1912-1913 Nobel Ammunition Price List sports a simple sans-serif "N" within a circle - the only time we have seen this particular mark.

This mark has not been seen on oilers, but it does give us something else to go on, should one show up. |

PARKER-HALE, LTD.

|

PARKER-HALE, LTD. Bisley Works, Whittal Street, Birmingham. [6]

Founded in the 1880's as A.G. Parker & Company, Ltd.; did not adopt the name Parker-Hale until 1936. Renamed P-H Arms 1940.

This is one of the few manufacturers whose logo is found on both Mk IV (brass) and Mk V (non-brass) oilers The P-H mark has only been seen on Mk IV oilers. |

|

PARKER-HALE, LTD. Bisley Works, Whittal Street, Birmingham. [6]

Founded in the 1880's as A.G. Parker & Company, Ltd.; did not adopt the name Parker-Hale until 1936. Renamed P-H Arms 1940.

The P-H within a triangle has only been seen on Mk V (non-brass) oilers. |

R&N LTD - UNKNOWN SOLDIER - ENGLAND

|

R&N LTD Unknown Soldier [4] [5]

Name not found in the 8,760 metalworking and similar firms listed in Ministry of Munitions lists 1916-1921. Closest name match is Ross & Nicoll (no Ltd.) a 26-person firm that did engine work for the Admiralty. Name not found in WWII (1939-1945) list of contractors.

Mk IV oiler, Broad Arrow marked, presumed British. No inspection/view mark. |

SPERRYN & COMPANY, LTD.

|

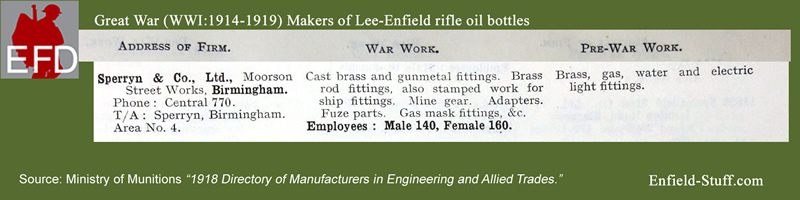

SPERRYN & COMPANY, LTD. Moorson Street Works, Birmingham. [4] [5]

Great War (1914-1919) contractor. [2] 100,000 produced. [3]

One maker with four variations of their own manufacturing mark? We've noted a tiny X, H and a * variously incorporated into the mark; the placement of which seems to vary from oiler to oiler.

We'll call the simplest version (left) Type One. |

|

SPERRYN & COMPANY, LTD. Moorson Street Works, Birmingham. [4] [5]

The version with a star/asterisk (left) is Type Two.

|

|

SPERRYN & COMPANY, LTD. Moorson Street Works, Birmingham. [4] [5]

The version with a floating X (left) is Type Three.

|

|

SPERRYN & COMPANY, LTD. Moorson Street Works, Birmingham. [4] [5]

The version with a floating H (left) is Type Four.

|

STANDARD SMALL ARMS COMPANY, LTD.

|

STANDARD SMALL ARMS COMPANY, LTD. No. 1 Lench Street, Birmingham [4] [5]

The Standard Small Arms Company (SSA) was formed in early 1915 with a business plan to contract parts and pieces of rifle production to various small firms to be assembled in a central location. At about the same time the government established the Ministry of Munitions to do exactly that, but for all aspects of war production. The privately owned/financed SSA was soon subsumed by the new government owned National Rifle Factory (NRF). Total rifle production for SAS/NRF is estimated about 250,000 units.

No idea about the number of oilers produced. Only 2-3 samples reported. BSA inspection/view marked. |

VICKERS, SONS & MAXIM / VICKERS, LTD.

|

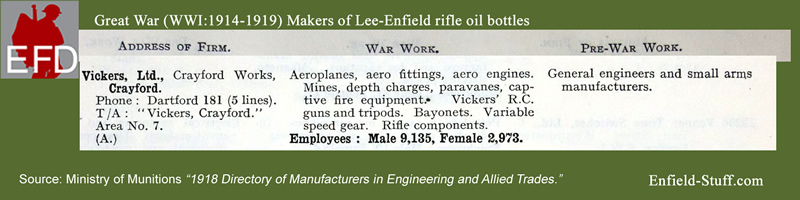

VICKERS, SONS & MAXIM Crayford Works, Crayford. [4] [5]

Great War (1914-1919) contractor. [2] 208,000 produced. [3]

Founded as Vickers, Sons & Company 1867, became Vickers, Sons & Maxim 1897, then Vickers, Ltd. in 1911 when the company got into aircraft manufacturing. The V.S.M appeared on ordnance and ammunition manufactured during the Great War (WWI; 1914-1919). |

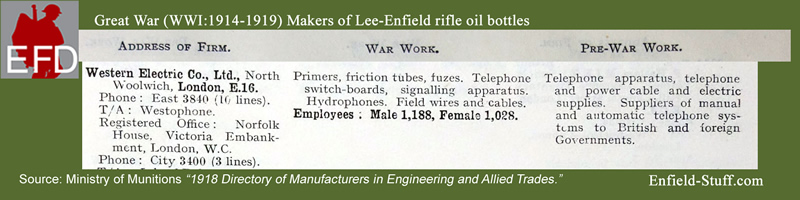

WESTERN ELECTRIC COMPANY, LTD.

Page Notes & Sources

[1] Photo and information found at the St Edmundsbury Chronicle 2000 website; used with permission (and with our thanks!) http://www.stedmundsburychronicle.co.uk/galleryww1/galleryww1page_08

Additional background information On War Service badges at the Imperial War Museum website: https://www.iwm.org.uk/history/on-war-service-badge

Additional information at the Imperial War Museum website on “Munitionettes” and the role of women munitions workers during World War I: https://www.iwm.org.uk/history/a-day-in-the-life-of-a-munitions-worker

[2] Great War contractors: Skennerton, Ian. The Lee-Enfield Story page 368; The Lee-Enfield pages 425-426.

[3] David Clarke, Hornchurch, Essex, UK has researched some of the official records during his many visits to the Enfield Pattern Room. He prepared a list of production contracts that were awarded to a number of vendors during the Great War (1914-1919). Unpublished. We are greatly indebted to Mr. Clarke; this information would not be available without his research.

[4] Grace's Guide to British Industrial History website: https://www.gracesguide.co.uk/Main_Page

[5] Birmingham Brass Makers website: https://www.oldcopper.org/makers/birmingham_brassmakers.php

[6] Cornell Publications website: http://www.cornellpubs.com/index.php reprints old gun catalogs, books and manuals dating from before 1850 to 2000+ and covering all aspects of firearms including Rifles, Shotguns, Pistols, Revolvers - Firearms, Sights, Telescopes and Ammunition of all sorts. Military and Civilian.

[7] Wikipedia: Ministry of Munitions https://en.wikipedia.org/wiki/Minister_of_Munitions

[8] Arms and The Wizard, Lloyd George and the Ministry of Munitions, 1915-1916; R.J.Q Adams, page 12.

[9] 1914-1918 OnLine: International Encyclopedia of the First World War; Shell Crisis of 1915: https://encyclopedia.1914-1918-online.net/article/shells_crisis_of_1915

Wikipedia: Shell Crisis of 1915: https://encyclopedia.1914-1918-online.net/article/shells_crisis_of_1915

[10] Arms and the Wizard; (see #8, above), pages 38-55.

[11] On her their lives depend: munitions workers in the Great War; Woollacott, Angela, pages 27-28.

Suggested Reading

|

Arms and the Wizard: Lloyd George and the Ministry of Munitions 1915-1916 (1978) 256 pages, end notes, index, bibliography, appendix.

|

|

On Her Their Lives Depend: Munitions Workers in the Great War (1994) 256 pages, footnotes, index, bibliography.

|

|

Official History of the Ministry of Munitions Volume XI: The Supply of Munitions Paperback. 662 pages. Appendicies.

|